.png)

IRUS - First in India to launch

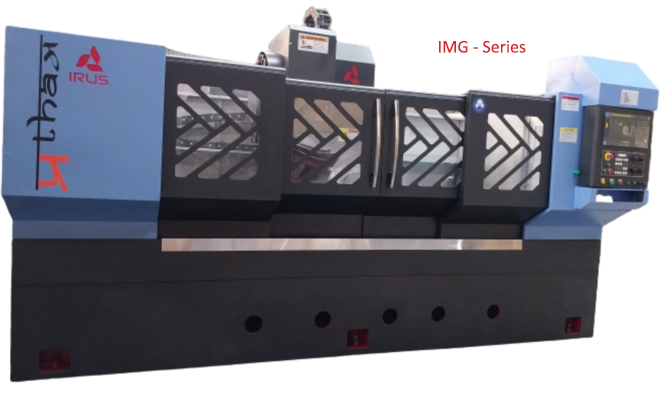

We IRUS Engineering Pvt. Ltd, feels proud to announce that, we are the First in India to launch its FIRST – LONG TRAVEL MOVING COLUMN MACHINING CENTER.

We take pride in our state-of-the-art high speed top gantry machining center. This cutting edge technology allows for precise and detailed machining of a variety of materials with a high degree of accuracy and efficiency. Our precision-engineered machinery is designed to help our customers achieve superior results every time. With this machining center, we are able to provide quality services to our clients and create products of exceptional quality

Industries that work with Robotics Gantries, Gantry Systems, Heavy Engineering, where machining of Large Components is required, IRUS make Long Travel Machining Center – fills the void space with its incredible Design,Spindle power and machine rigidity.

it’s a Must add Machining Center to your floor.

We IRUS offers Flexibility in machine accessories selection for affordable pricing.

Benefits :

- Extended Machining Range: Ideal for large and long components without repositioning, enabling precision machining over long travel axes.

- High Rigidity and Stability: Robust column design ensures consistent accuracy and vibration-free operation during heavy-duty machining.

- Space-Saving Design: Fixed table and moving column architecture optimize shop floor space compared to traditional gantry setups.

- Multi-Side Machining: Supports multiple operations (milling, drilling, tapping, boring) in a single setup, improving productivity.

- Customization Friendly: Flexible design allows integration of attachments like rotary tables, angle heads, or automatic tool changers.

- Enhanced Automation: Suitable for integration with pallet changers and robotic systems, boosting automation and efficiency.

- Reduced Setup Time: Machining of large or complex parts without realignment saves time and improves precision.

Application :

Heavy Engineering Components , Railway & Metro Industry , Defence and Aerospace, Energy Sector, Construction Equipment, Mould and Die Manufacturing, Power Transmission ..

SEND EnquiryIRUS - First in India to launch

- Table Size - 4600 x 600 mm

- X/Y/Z Axis Travel - 4500 x 500 x 580 mm

- ( available X - 2500, 4500, 6500, 8500 mm)

- ATC - Automatic Tool Changer

- Controller - Fanuc / Mitsubishi / Siemens