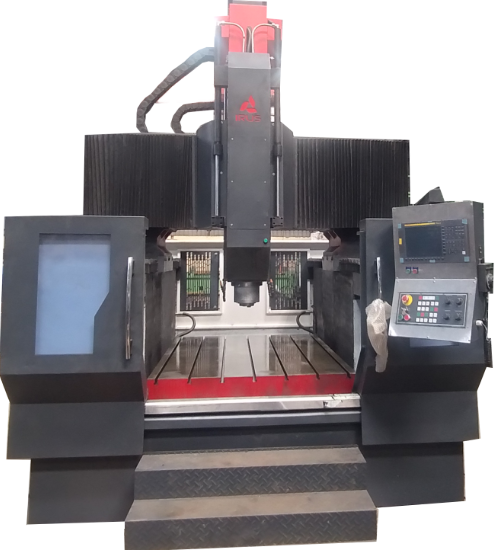

IMG Series- Gantry Moving Monoblock

IRUS make CNC Gantry Vertical Machining Center (VMC)

IRUS make CNC Gantry Vertical Machining Center (VMC) is a high-precision, heavy-duty machine designed for large-scale and complex machining applications. This type of machining center features a Gantry-Style Structure, where the bridge or beam moves along the worktable, allowing for greater stability, precision, and load-bearing capacity. It is widely used in industries such as Aerospace, Automotive, Mold and Die manufacturing, Energy, and Heavy Engineering.

Key Features :

Gantry-Style Structure

- Provides rigidity and stability, reducing vibrations and improving machining accuracy.

- Allows for large workpieces to be machined with precision.

High-Speed and High-Torque Spindle

- Equipped with a powerful spindle that offers high-speed cutting and deep milling capabilities.

- Supports various spindle speeds (e.g., 6000-24000 RPM), making it suitable for different materials like aluminum, steel, titanium, and composites.

Multi-Axis Capability (3-Axis, 4-Axis, and 5-Axis Options)

- Enables complex contour machining with simultaneous multi-axis movements.

- Ideal for aerospace parts, molds, and intricate components requiring precision in multiple dimensions.

Large Worktable & High Load Capacity

- Offers generous worktable dimensions to accommodate large parts.

- High load-bearing capacity for machining heavy components without compromising stability.

Advanced CNC Controller & Automation

- Integrated CNC control system (such as FANUC, Siemens, or Heidenhain) for accurate and efficient programming.

- Features real-time monitoring, adaptive control, and automation capabilities.

Precision Linear Guideways & Ballscrews

- High-precision linear guideways ensure smooth motion and increased tool life.

- Preloaded ballscrews minimize thermal expansion and maintain tight tolerances.

High-Speed Tool Changer (ATC)

- Automatic Tool Changer (ATC) enhances productivity by enabling quick tool changes.

- Reduces downtime and improves workflow efficiency.

Coolant & Chip Management System

- Efficient coolant systems keep the cutting zone clean and enhance tool longevity.

- Chip conveyor & filtration ensure smooth operation and easy maintenance.

Benefits:

- High Precision & Accuracy: The rigid gantry structure combined with advanced CNC controls ensures superior machining accuracy.

- Increased Productivity: Multi-axis capability and high-speed machining reduce cycle times and boost efficiency.

- Cost-Effective Manufacturing: Minimizes rework and scrap, reducing material waste and overall production costs.

- Versatility in Applications: Suitable for mold making, aerospace parts, energy sector components, heavy industrial machinery, and precision engineering.

- Enhanced Tool Life & Lower Maintenance: Precision guideways and automatic lubrication systems extend machine and tool lifespan.

- Capable of Handling Large & Heavy Workpieces: Ideal for industries requiring large-scale and high-precision machining.

Applications :

- Aerospace Components (wing spars, engine parts)

- Automotive Parts (chassis, die molds)

- Mold & Die Manufacturing

- Energy Industry (Wind, Oil & Gas, Nuclear)

- Shipbuilding & Railways

- Defence & Heavy Engineering

IMG Series- Gantry Moving Monoblock

|

Items |

Unit |

IMG 1200 |

IMG 1600 |

IMG 2200 |

IMG 3200 |

|

Work Table & Travel |

mm x mm |

1400x 1200/1600/2200/3200 |

1800x 1600/2200/3200 |

2400x 2200/3200/4200/6200 |

3400x 1600/3200/4200/6200 |

|

Travel - X |

mm |

500 |

600 |

800 |

1000 |

|

Travel - Y |

mm x mm |

400 / 500 |

500 / 500 |

600 / 550 |

800 / 600 |

|

Travel - Z |

mm |

700 (850) |

700(850) |

850(1000) |

850(1000) |

|

T- Slot |

No. x width |

7x22x160 |

|||

|

Maxi. Load on Table |

Kg |

4000 |

5000 |

6000 |

8000 |

|

Face to Table Top |

mm |

150-850(1000) |

150-850(1000) |

150-1000 |

150-1000(1000) |

|

Feed |

|

|

|

|

|

|

Rapid (X/Y/Z) |

m/min |

30/20/20 |

20/20/20 |

20/20/20 |

20/20/20 |

|

Feed (X/Y/Z) |

m/min |

10 |

10 |

10 |

10 |

|

Guideway (X/Y/Z) |

|

Linear Roller Guideways |

|||

|

Spindle |

|

|

|

|

|

|

Spindle Taper / Range |

RPM |

BT 40 (50) /9000/6000 |

BT 40 (50) /9000/6000 |

||

|

Spindle Power |

Kw |

11/15 |

15/18.5 |

15/18.5 |

15/18.5 |

|

Axis Motor (X/Y/Z) |

Kw |

4 / 3 / 5 |

|||

|

Accuracy |

|

|

|||

|

Positioning (X/Y/Z) |

mm |

+ 0.005/300 |

|||

|

Repeatability (X/Y/Z) |

mm |

+ 0.005/300 |

|||

|

Tool Storage Capacity |

|

20 / 24 / 40 |

|||

|

CNC Controller |

|

Mitsubishi / Fanuc / Siemens |

|||