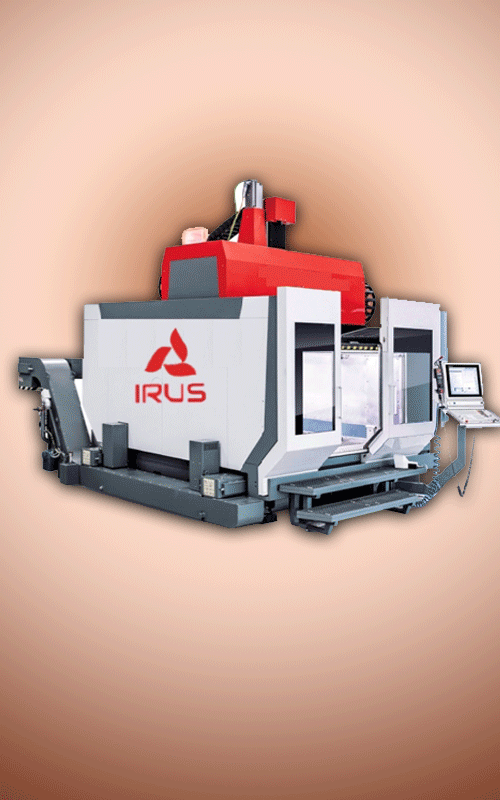

IMG Series - CNC 4 Axis Gantry Vertical Machining Center

IRUS Engineering has meticulously engineered its CNC 4-Axis Gantry Vertical Machining Center to cater to the most demanding machining requirements. Here are some of the standout features that set it apart:

Key Features :

- Advanced Kinematic Design: Ensures precise and efficient multi-axis movements, enhancing machining accuracy.

- High-Speed and High-Torque Spindle: Capable of handling a variety of materials with optimal cutting performance.

- Intelligent Control System: Incorporates smart technologies for real-time monitoring and adaptive control, improving operational efficiency.

- Rigid and Stable Construction: Designed to minimize vibrations, ensuring consistent precision during operations.

- Automation and IoT Integration: Facilitates seamless integration into smart manufacturing environments for enhanced productivity.

Benefits :

- Reduced Setup Time: Multi-axis capabilities allow for machining complex parts in a single setup, increasing efficiency.

- High Precision: Delivers superior accuracy, essential for industries like aerospace and medical device manufacturing.

- Cost Savings: Minimizes tooling and labor costs through efficient machining processes

- Material Utilization: Optimizes material usage, reducing waste and associated costs.

Applications :

Thanks to its versatility and high precision, IRUS make CNC 4-Axis Machining Center finds applications in various industries where accuracy and efficiency are paramount. Some of the key sectors that benefit from this technology include: Aerospace Industry, Medical / Pharmaceuticals, Automotive, Die & Mold, Energy, Defense, Railways..

SEND Enquiry

IMG Series - CNC 4 Axis Gantry Vertical Machining Center

Specification

|

Items |

Unit |

IMG 540 |

IMG 650 |

IMG 860 |

IMG 1080 |

|

Work Table & Travel |

mm x mm |

700 x 400 |

800 x 500 |

1000 x 600 |

1200 x 1000 |

|

Travel ( X ) |

mm |

500 |

600 |

800 |

1000 |

|

Travel (Y / Z) |

mm x mm |

400 / 500 |

500 / 500 |

600 / 550 |

800 / 600 |

|

T- Slot |

No. x width |

4x18x100 |

4x18x100 |

4x18x100 |

4x18x100 |

|

Maxi. Load on Table |

Kg |

4000 |

5000 |

6000 |

8000 |

|

Face to Table Top |

mm |

100 |

150-650 |

150-650 |

150-650 |

|

Table Variants |

|

A-Axis (4Axis) and A/C Axis (5 Axis) |

|||

|

Feed |

|

|

|

|

|

|

Rapid (X/Y/Z) |

m/min |

30/30/30 |

30/30/30 |

30/30/30 |

30/30/30 |

|

Guideway (X/Y/Z) |

|

Linear Roller Guideways |

|||

|

Spindle |

|

|

|

|

|

|

Spindle Taper / Range |

RPM |

BT 40/ 9000 |

BT 40/ 9000 |

||

|

Spindle Power |

Kw |

5.5/7 |

7.5/11 |

7.5/11 |

7.5/11 |

|

Axis Motor (X/Y/Z) |

Kw |

2 / 2 / 3 |

|||

|

Accuracy |

|

|

|||

|

Positioning (X/Y/Z) |

mm |

+ 0.005/300 |

|||

|

Repeatability (X/Y/Z) |

mm |

+ 0.003/300 |

|||

|

Tool Storage Capacity |

|

20/24/30 |

|||

|

CNC Controller |

|

Mitsubishi / Fanuc / Siemens |

|||